Metal recycling doesn’t always happen the same way every time. Many variables exist and different groups handle metal recycling in different ways. Some groups only handle a particular type or grade of metal. In almost all cases, you can break metal recycling down into a few common steps.

The Collection Process

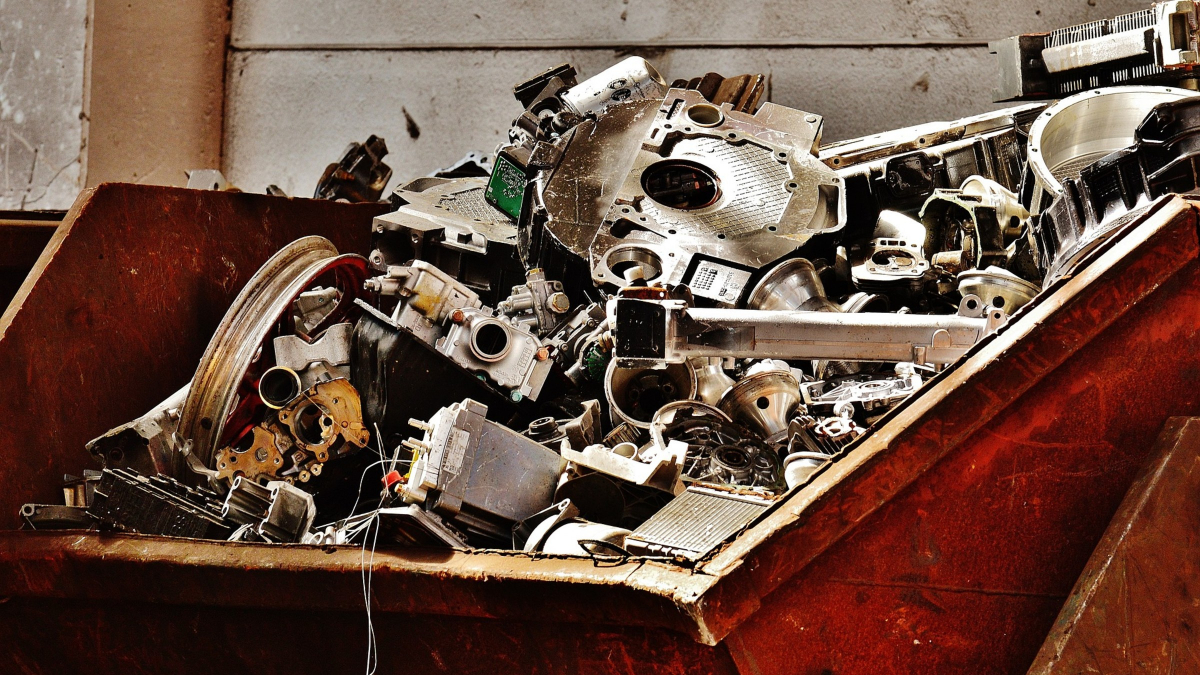

Before anything can happen, a person or group must first collect the metals. This can happen in several ways. Some places rely on people or businesses to bring in metals for recycling. Some other recyclers and scrapyards outright purchase scrap metal.

Generally, scrap metal yards do most of the collecting. Some private businesses or public initiatives may also hold drives or establish centers for scrap metal collection.

The Sorting Process

People make use of many types of metals and in different ways. Not all metal is the same, so groups that collect metal must then sort the metals. One broad separation is the separation of ferrous from non-ferrous metals. Ferrous metals contain iron while non-ferrous metals do not.

Outside of that broad difference, different places will value different types of metals. Consider that you would want a product made from recycled metal to still hold to quality standards. To that end, metal recyclers often sort metals by quality standards as well.

The sorting process also includes cleaning the metals. Recycled metals often come with particles of dirt, food, paint, and other contaminants. These contaminants can end up in the finished product if they’re left on the metals.

Metal Processing Routines

The metal processing part of the recycling process is the most intensive. Depending on the metal and the goals of the recycler, the metal will go through many processing steps.

Compacting – Once a recycler has all the metals of a specific type or quality, they will then compact it. Machines will squeeze and squash the metal together so it doesn’t take up as much space. Compacting metal also makes it easier for shipping or further processing.

Shredding – Recyclers will turn the compacted metal into metal sheets or other types of metal blocks. This is to make the metal more suitable for particular types of processing tasks, such as melting.

Melting – Metal sheets or blocks go into a furnace at a temperature specific to the type of metal. Melting makes the metal more malleable and does some purification as well.

Purification – The dedicated purification process exists to eliminate contaminants and other metal types that don’t belong in the final batch. Different types of metals require different types of processes and machines to help purify them.

Consolidation –Here is where recyclers rejoin the more malleable and clean metals into dense blocks or sheets. If the recycler went through this process for a specific product, the metal is sometimes shaped into that proper shape at this part of the process. This typically includes bars, plates, or sheets of metal of the right type and size.

4. Transporting the Metals

Finally, the metal bars or products go through whatever packaging and shipping routines required. The metal goes onto trucks or other conveyances. The recycler ships it out to warehouses, factories, and manufacturing plants globally.

This whole process helps to preserve natural resources, protect the environment, and reduce overall energy consumption. The recycling process also employs thousands of people and creates new jobs.

Recycling helps keep costs low on all the products you enjoy made or containing metal. Recycling literally boosts the local, national, and global economy. So you can feel great about doing your part.

Comments