CNC or Computer Numerical Control machines can be described as electro-mechanical devices that make use of computer programming tools to manipulate machine shop tools. CNC normally represents two very common methods used in generating prototypes from digitalized software sleeves. The two methods are FDM and 3D printing like SLM/SLS.

The very first CNC machine was developed in the 40’s. This machine relied on the use of a telecommunication data storage that was referred to as perforated paper tape or punched tape. Today, the technology is obsolete as it was replaced with analog technology, which was then replaced by the digital technology.

How Does CNC Work?

In general, machining involves transforming stock material pieces, e.g., plastic blocks into finished products. This is done through a process known as controlled material removal. CNC relies on digitalized instructions provided by CAM (Computer Aided Manufacturing), just like all the other technologies used in prototype development. The CNC machines used at Holtwood machine then interprets the design as instructions on how to cut the prototype parts.

Being able to program the computer devices to be able to control the machine tools greatly enhances shop productivity. This is due to the automation of the labor-intensive processes. Automation increases the accuracy and speed with which the prototype parts get created.

Types of CNC Machines

CNC machines can be categorized into two main groups: novel machining technology and conventional machining technologies. This can further be broken down into various subcategories.

Conventional Machining Technologies

- Drills: they function by spinning the drill bit as well as moving this bit until it comes into contact with the stationary block of material.

- Lathes: this is the inverse of a drill. Rather than spin the drill, they spin the material block against the bit. They make contact with the stock block of material by moving the cutting tool in a parallel manner until it comes into contact with the spinning material.

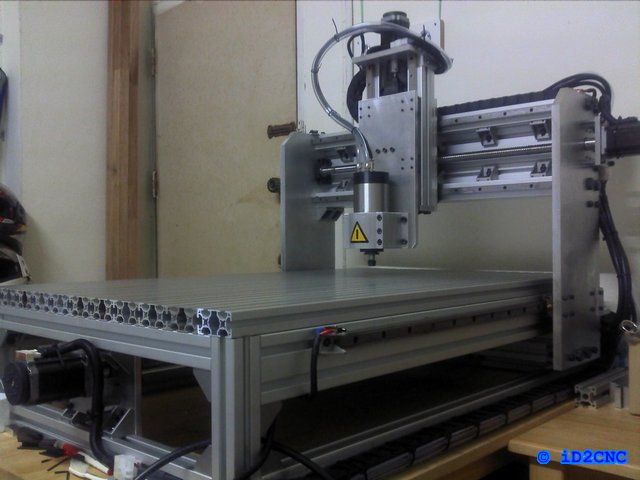

- Milling machines: these are the most popular CNC machines in use at the moment. They use rotary tools when removing material from a stock unit.

Novel Technologies

- Chemical or Electrical Machining: novel technologies that utilize specialized techniques when cutting materials include electrochemical machining, photochemical machining, and electron beam machining.

- Additional Cutting Mediums: other types of novel technologies that are used in cutting materials include plasma cutting machines, laser cutting machines, waterjet technology, and oxy-fuel cutting machines.

CNC machines can process almost all types of materials. It all comes down to the applications. But the materials that are mainly used with these machines include titanium, wood, aluminum, brass, plastics, fiberglass, and foam.

CNC machines are mainly used in manufacturing as a majority of the novel CNC machines have been built for the machine niche specifically. For instance, electrochemical machining is used primarily in slicing up high durable metals that are otherwise not feasible. As such, you will find that the conventional CNC machining tools are mostly used during the prototype development process as opposed to manufacturing.

Comments